Having an open tank of solvent is its own issue, but the 3D Design Express team is working on a way to make the system airtight, so this may or may not end up being a problem. (16.51 x 16.51 x 20.32 cm), but the design seems simple enough that it could be upgraded to handle larger parts. Currently the 3D Refiner can only handle parts up to 6.5 x 6.5 x 8 in. The end result is an object without the obvious, chunky strata that is the usual result of low resolution material extrusion.

The plate spins the part in the solvent and, after a few minutes, the newly smoothed part is retracted and left to dry.

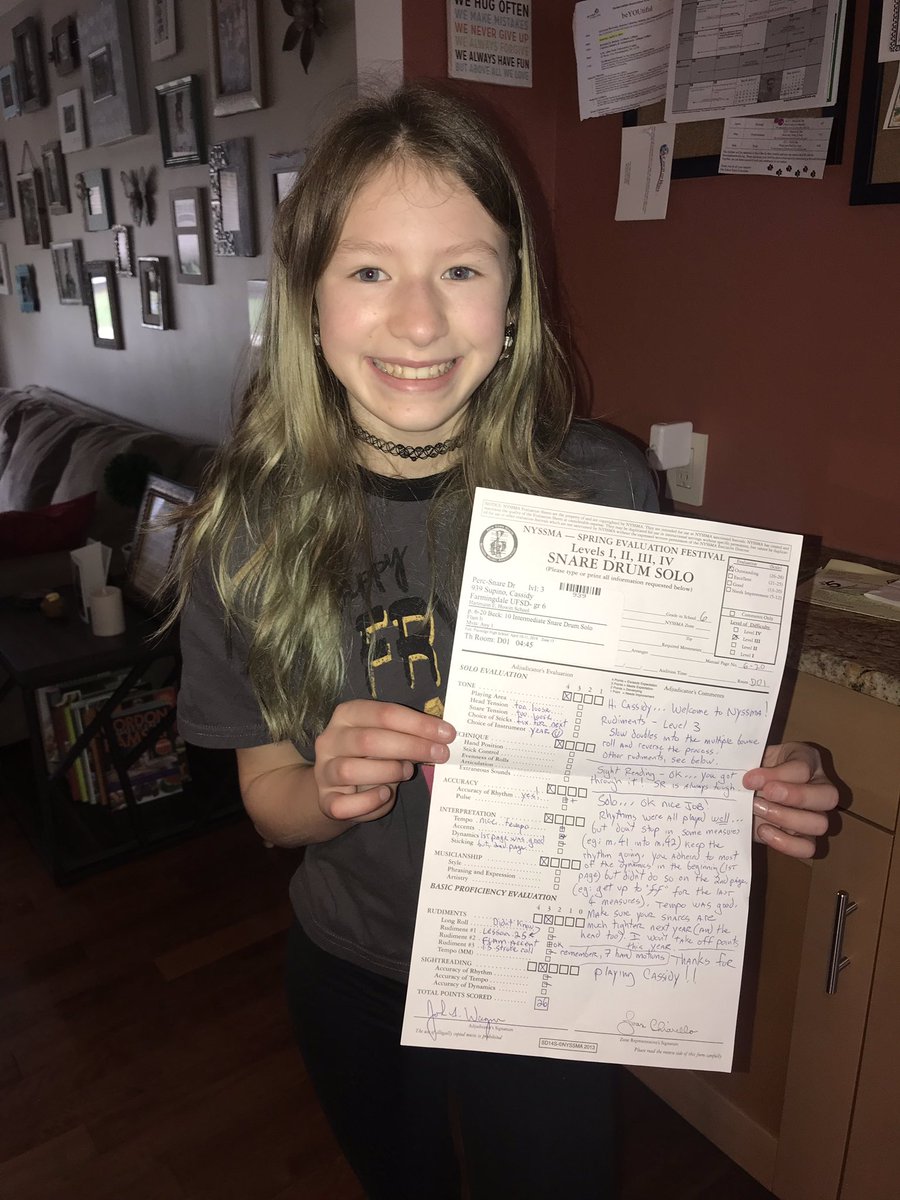

We are extremely proud of Elise, Gavin and Kara who have spent countless hours on their craft, said Katie Derrenbacher, Jamestown High School orchestra director. The 3D Refiner operates by strapping a finished part to a plate that is then lowered into a solvent tank. Jamestown High School students Elise Jones, Gavin Card and Kara Triscari represented the school at NYSSMA’s All-State Conference in Rochester. The mission of the New York State Council of Administrators of Music Education is to provide a source of communication, development, and support for all leaders responsible for facilitating the music education of the students of New York State.

The end result of their work was the 3D Refiner. Rather than resigning themselves to longer waits, the students began experimenting with ways to refine low resolution prints. 3D Prints Express was started by two engineering students at UC Berkley who love 3D printing, but arent so keen on waiting for high resolution prints. 3D Prints Express was started by two engineering students at UC Berkley who love 3D printing, but aren’t so keen on waiting for high resolution prints.

0 kommentar(er)

0 kommentar(er)